We were first contacted by the customer to carry out a power management installation to a bare Airstream shell, but as the job progressed, we were requested to carry out further works. What we ended up building was a handmade, bespoke beautiful vintage Airstream caravan.

I will separate each section of the build and explain each process, it makes sense to start from the bottom and work up.

When we first collected the caravan, the chassis had already been converted to UK specification running gear, unfortunately whoever carried out this work did not weigh the caravan to find out the weight limit of the axle required. The maximum capacity of the axle they fitted was 1500kg, when the van was empty it weighted just under 1400kg. It was going to prove difficult to completely kit out a bespoke Airstream Caravan, and keep the weight of everything we installed to under 100kg, so a chassis upgrade was necessary. After some careful calculations we found that the final vehicle weight would be between 2200kg – 2500kg, with some lengthy conversations with the technical team at Knott – Avonride, we decided on the following configuration:

We installed a 3500kg capacity Knott Avonride axle, this was manufactured to bolt onto the original chassis rails. Having this weight capacity on a single axle meant the hub and brake size would have to be increased, this presented an issue as the original 15” wheel rims would not fit over the new drums. We needed to find a 16” wheel rim and tyre that would carry a minimum of 1400kg per rim. We installed Landrover Wolf steel wheels and 121 rated tyres. This limited our maximum load to 2800kg, we deemed this would be more than enough. We also upgraded the hitch to a 3000kg unit fitted with the new Knott stabiliser hitch.

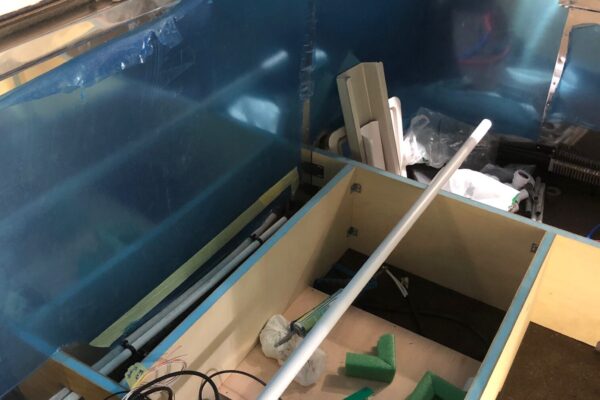

Furniture

Even though we had updated the chassis considerably, we still needed to keep any eye on the weight, as we wanted to ensure the customer had plenty of payload. We looked at many possible products and we decided to use Coretex board, this was ideal as we could increase the thickness to 30mm without increasing the weight. This made the board stiffer and lighter than an equivalent sized light weight furniture board commonly used in camper conversions. All the finishing trims were constructed from black American walnut, luckily we were able to source a large section of this rare wood, the section was premium grade so once it was machined it looked stunning. Due to the age of the Airstream, you must expect a certain amount flex in the body while it is being towed we ensured all the cupboard catches could be positively locked, this will prevent any cupboards flying open when the caravan is being towed. We made a bespoke shower tray in the toilet area, this was achieved by building the tray from marine grade plywood and then spraying it with Speedcoat, this gave us a watertight durable finish. The toilet area was fitted with a sliding door as this was the best space saving option.

Power Management and electrical system.

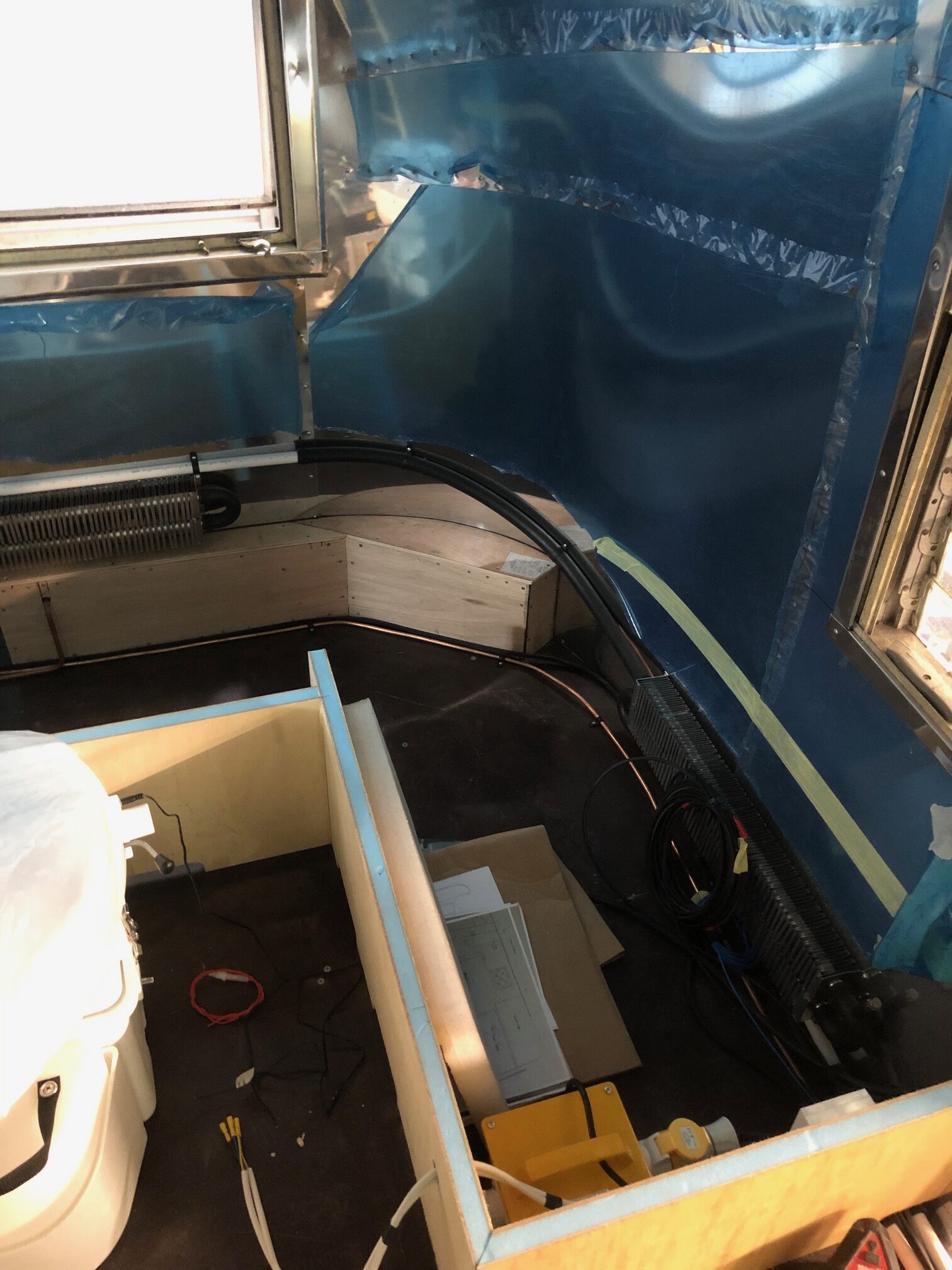

The customer wanted to be able to pitch the van anywhere and still have everything working, to achieve this we need a off grid system. We started with two Transporter Energy Lithium batteries, these batteries have over 5000 discharges at 80% and a 10 year warranty. We installed a 2kva Victron Multiplus with a remote switch incorporating the grid assist control, the system was monitored by a Victron BMV battery monitor. A full colour coded DC wiring loom and an AC loom was produced. The original air conditioner was left in place, but this was a 110v unit, we installed a voltage dropper to allow this to operate. We installed 2 solar panels on the roof, 1 x 100w and 1 x 150w these were controlled by 2 independent Victron MPPT charge controllers. We also added a power line to the front of the caravan terminating in a Anderson plug so additional portable solar panels can be added if necessary.

Plumbing a heating

We installed an Alde wet central heating system, there were a number of reasons for this choice, firstly the system is almost silent as it has not noisy fans to distribute the heat, it could be roof flued which we felt was quite important ascetically. Radiators were installed all around the caravan and a heated towel rail was installed in the toilet area. An internal water tank was installed with a Shurflo pressure pump, this allowed the installation of domestic taps which were more in keeping with the design. An underslung waste tank was installed with easy access for draining.

Gas system

We installed polished Alugas refillable cylinders on the A-frame, these don’t only look good, but they are also light. We installed a Thetford Triplex oven and a Thetford 3-way fridge.